.

.

| FAQ |

| 1) What is your main products? |

| Threaded rod, Hex bolt, Hex Nut, Flat washer, Screws, Anchors, Blind rivet, etc |

| 2) Do you have MOQ for your product? |

| It depends on sizes, Usually 200 kgs to 1000 kgs. |

| 3) How about your delivery time? |

| From 7 days to 75 days, depends on your sizes and quantity. |

| 4) What is your payment term? |

| T/T, LC, DP, etc. |

| 5) Can you send me a price list? |

| Due to a lot of kinds of fasteners, we quote prices accoridng to sizes, quantity, packing only. |

| 6) Can you provide samples? |

| Sure, free sampls will be provided |

Manufacturer Customization Stainless Dowel Pins 304 Stainless Steel Taper Pin

| Standard: | GB877/JIS13531/DIN1/DIN6325/DIN7978 |

| Diameter: | 1/4"-2 1/2",M4-M64 |

| Length: | ≤800mm or 30" |

| Material: | Carbon Steel, Alloy Steel, Stainless Steel, Brass |

| Grade: | SAE J429 Gr.2, 5,8; ASTM A307Gr.A, Class 4.8, 5.8, 6.8, 8.8, 10.9, 12.9;A2-70, A4-70,A4-80 |

| Thread: | METRIC,UNC,UNF,BSW,BSF |

| Standard | DIN, ISO, GB and ASME/ANSI, BS, JIS |

| Coating | Black. |

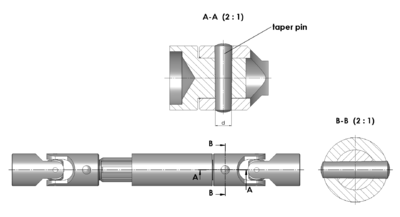

A taper pin is a fastener used in mechanical engineering. They are steel rods with one end having a slightly larger diameter than the other. Standard inch-sized taper pins have a taper on diameter of 1:48[1] while metric ones have a taper of 1:50.[2] (A 1:48 taper means that one end of a 4-foot-long bar (48 inches) will be 1 inch smaller in diameter than the other end, or a 1⁄4-inch taper over a 1-foot length. A 1:50 taper means that one end of a half-meter long bar (50 cm) will be 1 cm smaller in diameter than the other end, or a 2 mm taper over a decimeter length.) A taper pin is a fastener used in mechanical engineering. They are steel rods with one end having a slightly larger diameter than the other. Standard inch-sized taper pins have a taper on diameter of 1:48[1] while metric ones have a taper of 1:50.[2] (A 1:48 taper means that one end of a 4-foot-long bar (48 inches) will be 1 inch smaller in diameter than the other end, or a 1⁄4-inch taper over a 1-foot length. A 1:50 taper means that one end of a half-meter long bar (50 cm) will be 1 cm smaller in diameter than the other end, or a 2 mm taper over a decimeter length.)

A taper pin is a fastener used in mechanical engineering. They are steel rods with one end having a slightly larger diameter than the other. Standard inch-sized taper pins have a taper on diameter of 1:48[1] while metric ones have a taper of 1:50.[2] (A 1:48 taper means that one end of a 4-foot-long bar (48 inches) will be 1 inch smaller in diameter than the other end, or a 1⁄4-inch taper over a 1-foot length. A 1:50 taper means that one end of a half-meter long bar (50 cm) will be 1 cm smaller in diameter than the other end, or a 2 mm taper over a decimeter length.) A taper pin is a fastener used in mechanical engineering. They are steel rods with one end having a slightly larger diameter than the other. Standard inch-sized taper pins have a taper on diameter of 1:48[1] while metric ones have a taper of 1:50.[2] (A 1:48 taper means that one end of a 4-foot-long bar (48 inches) will be 1 inch smaller in diameter than the other end, or a 1⁄4-inch taper over a 1-foot length. A 1:50 taper means that one end of a half-meter long bar (50 cm) will be 1 cm smaller in diameter than the other end, or a 2 mm taper over a decimeter length.)