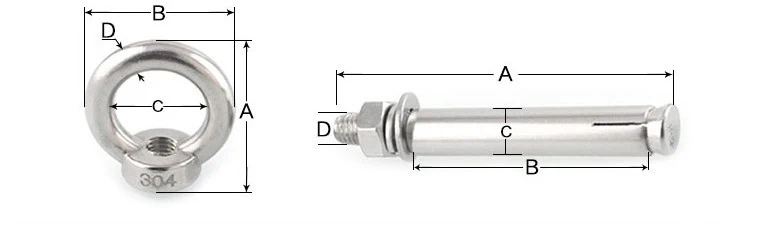

Eye bolt sleeve anchor is a kind of medium-sized preassembled torque controlled concrete mechanical expansion anchor, which is composed of an eye bolt made by cold punching, a cone nut and a pressed carbon steel sleeve. Its expansion function is that the cone nut expands with the upward rotation of the external threads of the eye bolt when tightening , so as to form an expansion mechanism and lock it on the hole wall. ▲Using hammer bit and carbide bit, drill a hole in the base materials with the same diameter as the anchor, at least 12 mm to 24 mm deeper than the expected embedment depth. ▲Use a brush or compressed air to remove all debris from the hole. ▲ Align the nut with the top of the sleeve anchor. ▲ Insert the sleeve anchor through the fixture and into the hole of the substrate until the washer and nut are close to the fixture. ▲ Turn the nut until it is tightened by hand, and then turn the hex nut with a spanner, or directly use a hard object to pass through the eye bolt and turn the head clockwise to fix the anchor.

Eye bolt sleeve anchor is a kind of medium-sized preassembled torque controlled concrete mechanical expansion anchor, which is composed of an eye bolt made by cold punching, a cone nut and a pressed carbon steel sleeve. Its expansion function is that the cone nut expands with the upward rotation of the external threads of the eye bolt when tightening , so as to form an expansion mechanism and lock it on the hole wall. ▲Using hammer bit and carbide bit, drill a hole in the base materials with the same diameter as the anchor, at least 12 mm to 24 mm deeper than the expected embedment depth. ▲Use a brush or compressed air to remove all debris from the hole. ▲ Align the nut with the top of the sleeve anchor. ▲ Insert the sleeve anchor through the fixture and into the hole of the substrate until the washer and nut are close to the fixture. ▲ Turn the nut until it is tightened by hand, and then turn the hex nut with a spanner, or directly use a hard object to pass through the eye bolt and turn the head clockwise to fix the anchor.

| Product name | Eye bolt sleeve anchor |

| Standard | DIN, ASTM/ANSI JIS EN ISO, AS, GB |

| Material | Stainless Steel: SS201, SS303, SS304, SS316, SS316L, SS904L, F593 Steel Grade: DIN: Gr.4.6, 4.8, 5.6, 5.8, 8.8, 10.9, 12.9; SAE: Gr.2, 5, 8; ASTM: 307A, 307B, A325, A394, A490, A449, |

| Finishing | Zinc(Yellow, White, Blue, Black), Hot Dip Galvanized(HDG), Black Oxide, Geomet, Dacroment, anodization, Nickel plated, Zinc-Nickel plated |

| Production Process | M2-M24:Cold Froging, M24-M100 Hot Forging, Machining and CNC for Customized fastener |

| Customized Products Lead time | Busy season:15-30days, Slack seaon:10-15days |

| Stock Products | Steel:4.8Grade DIN6923, 8.8Grade 10.9Grade of GB5783 and GB5782 Stainless steel: All DIN Standard stainless steel Bolt |

| Specification | Length (L1) (mm) | Case Tube Length (L2) (mm) | Diameter (mm) | Case Tube Diameter (mm) | Hole Diameter (mm) | Wrench Size (mm) |

| M6X50 | 50 | 35 | 6 | 8 | 8 | 10 |

| M6X60 | 60 | 40 | 6 | 8 | 8 | 10 |

| M6X70 | 70 | 50 | 6 | 8 | 8 | 10 |

| M6X80 | 80 | 55 | 6 | 8 | 8 | 10 |

| M6X100 | 100 | 80 | 6 | 8 | 8 | 10 |

| M8X50 | 50 | 30 | 8 | 10 | 10 | 13 |

| M8X60 | 60 | 40 | 8 | 10 | 10 | 13 |

| M8X70 | 70 | 50 | 8 | 10 | 10 | 13 |

| M8X80 | 80 | 55 | 8 | 10 | 10 | 13 |

| M8X90 | 90 | 65 | 8 | 10 | 10 | 13 |

| M8X100 | 100 | 75 | 8 | 10 | 10 | 13 |

| M8X120 | 120 | 90 | 8 | 10 | 10 | 13 |

| M8X150 | 150 | 120 | 8 | 10 | 10 | 13 |

| M10X60 | 60 | 35 | 10 | 12 | 12 | 17 |

| M10X70 | 70 | 45 | 10 | 12 | 12 | 17 |

| M10X80 | 80 | 55 | 10 | 12 | 12 | 17 |

| M10X90 | 90 | 60 | 10 | 12 | 12 | 17 |

| M10X100 | 100 | 75 | 10 | 12 | 12 | 17 |

| M10X110 | 110 | 85 | 10 | 12 | 12 | 17 |

| M10X120 | 120 | 90 | 10 | 12 | 12 | 17 |

| M10X150 | 150 | 120 | 10 | 12 | 12 | 17 |

| M12X80 | 80 | 50 | 12 | 14 | 14 | 19 |

| M12X90 | 90 | 65 | 12 | 14 | 14 | 19 |

| M12X100 | 100 | 70 | 12 | 14 | 14 | 19 |

| M12X110 | 110 | 80 | 12 | 14 | 14 | 19 |

| M12X120 | 120 | 90 | 12 | 14 | 14 | 19 |

| M12X150 | 150 | 100 | 12 | 14 | 14 | 19 |

| M12X200 | 200 | 150 | 12 | 16 | 16 | 19 |

| M14X100 | 100 | 60 | 14 | 18 | 18 | 22 |

| M14X120 | 120 | 80 | 14 | 18 | 18 | 22 |

| M14X150 | 150 | 90 | 14 | 18 | 18 | 22 |

| M14X200 | 200 | 150 | 14 | 18 | 18 | 22 |

| M16X100 | 100 | 60 | 16 | 20 | 20 | 24 |

| M16X120 | 120 | 80 | 16 | 20 | 20 | 24 |

| M16X140 | 140 | 90 | 16 | 20 | 20 | 24 |

| M16X150 | 150 | 100 | 16 | 20 | 20 | 24 |

| M16X200 | 200 | 150 | 16 | 20 | 20 | 24 |

| M16X400 | 400 | -- | 16 | 20 | 20 | 24 |

| M20X100 | 100 | 45 | 20 | 25 | 25 | 29 |

| M20X120 | 120 | 65 | 20 | 25 | 25 | 29 |

| M20X150 | 150 | 85 | 20 | 25 | 25 | 29 |

| M20X200 | 200 | 145 | 20 | 25 | 25 | 29 |

| M20X250 | 250 | 180 | 20 | 25 | 25 | 29 |